Tank Mixers from I.B. Engineering

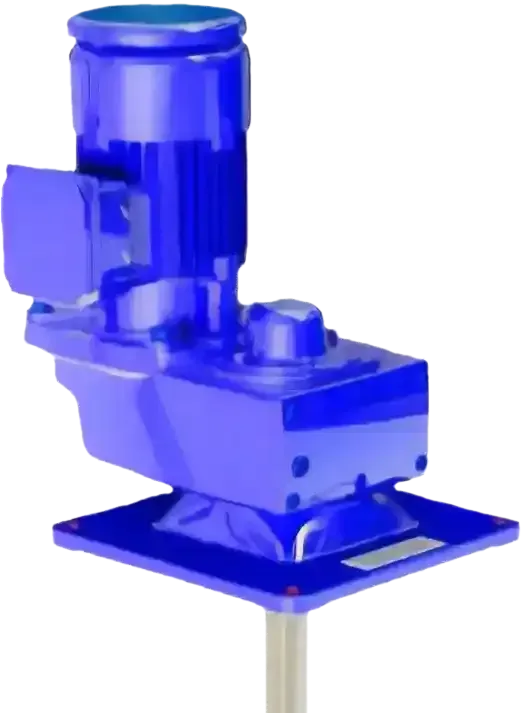

Top Entry Tank Mixers and Agitators

The Euromixers range of Top Entry Heavy Duty Tank Mixers and Agitators offer a robust, reliable and cost-effective solution for a wide spectrum of mixing / agitating applications, mixer power shaft speed and impeller type are expertly configured by our application engineers for each application to ensure optimum performance.

Using the IBC as a mixing vessel ensures consistent product quality and offers significant cost savings on transfer and cleaning time.

Modular design provides the flexibility to meet a variety of options including Low Headroom Helical bevel gearbox where headroom is at a premium. The mixer can be mounted on support beams or a suitable structure for open tank operation or pedestal mounted for closed tanks with a stuffing box or single / double mechanical seals.

Features include:

- Versatile modular design for Open or Closed top tanks.

- Compact robust design.

- SF 1.50 minimum service factor for long trouble free operation

- High efficiency in line helical gear drives with IE3 energy efficient electric motors.

- Ground gears for efficiency and low noise

- Hollow shaft gearbox to ensure accurate mixer shaft alignment

Modular Design Tank Mixers

Gear Driven

EM tank mixer gear drives are designed on a robust rigid structure enabling high bending loads, the mixer output shaft is supported by heavy duty taper roller bearings with a minimum L10 design life of 100,000 hours, gears are ground for low noise and long service life as standard. The rugged EM cast iron gearbox is fitted with double lip seal to effectively contain the gearbox lubricant under extreme operating conditions.

Shaft Design

The mixer shaft is designed to operate below first critical speed in air and is suitable for operation at all fluid levels in tank, or with an inverter at frequencies up to 50 Hz, and to run smoothly without vibration at all speeds.

Shafts can be supplied in 304 or 316 stainless steel as standard with optional plastic or rubber covered shafts and impellers.

Impeller Technology

Impellers are selected by our application engineers to meet your specific process requirements ranging from E-300 highest efficiency turbulent flow impeller which are ideal for blending, heat transfer, and solids suspension applications.

E-400 or E-315 impellers are a good choice where the viscosity changes over a wide range causing the flow regime to vary between turbulent and laminar flow and solids suspension applications, through to spiral and anchors for more viscous products.

Tank mixers and Agitators for closed tanks can be provided fitted with a stuffing box, Single or Double mechanical seals to suit the specific application, on standard EM models the mixer drive is removed to change the mechanical seal and offers the most economical solution on small drives.

Closed Tanks

Single Mechanical Seals

Single Dry running balanced mechanical seal design reduces seal face wear by reducing the seal face pressure as process pressure fluctuates, the seals have self-lubricating seal faces, no external cooling or lubrication is required.

The design and material selection meet the needs of the pharmaceutical and chemical processing industries – they are excellent for low duty mixing applications and operation in vacuum conditions. The seal can be supplied with a debris well to capture wear particles, preventing the contamination of process fluid.

Double Mechanical Seal Catridges

Are available in a variety of materials to meet critical and demanding pressure and temperature ratings.

HM Model Tank Mixers and Agitators provide the facility to change the mechanical seal cartridge without removing the drive and also offer a wider range of seal types.

Need more information?

If you're not sure what type of mixer you need, or would like more information, please get in touch and we can organise a video or on-site inspection of your premises to work out your ideal mixing solution.

Contact Us

We will get back to you as soon as possible

Please try again later

Copyright © 2024 I.B. Engineering Pty Ltd

site by mulcahymarketing.com.au