I.B. Engineering

Static Mixers

Static mixers and Heat Exchangers are used for a wide range of applications including mixing, heat exchange and dispersion. Due to numerous unique innovations our products are especially suitable for hygienic processes where CIP (cleaning in place) is required, and also a broad range of temperatures and viscosities.

Using the IBC as a mixing vessel ensures consistent product quality and offers significant cost savings on transfer and cleaning time.

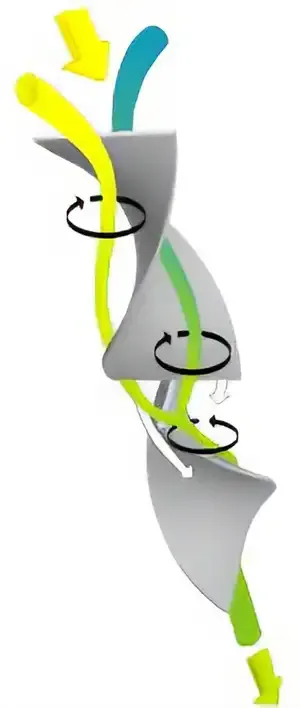

Flow through the static mixer element is diverted into two separate streams. Optimization of the profile induces equal radial and axial flow. The helix pitch creates a rotation of the fluid, by which the fluid flows from the outside to the inside and reverse. The difference in velocity that occurs creates a shearing of the fluids.

After one rotation through the static mixer element a second diversion takes place and simultaneously a reverse of the succeeding rotation in the next mixing element occurs. As the number of streams or layers increases, the layer thickness decreases. After only 20 rotations in a 50mm diameter Static mixer, mixing at molecular level is achieved. 20 diversions of the fluid creates 220 separate layers, each 0.05 micron thick.

Applications:

- General chemicals – agric-chemicals, paint, slurries.

- Polymers – polyesters, nylons, ethylenes, silicones adhesives, sealants.

- Food & Beverages – sauces, chocolates, dairy products,

salad dressing, sugar syrups. - Energy – petrochemicals, fuel oil.

- Pulp & Paper – Kraft soaps, black liquor, oils.

- Waste water treatment applications.

Our most popular sizes of static mixers manufactured in stainless steel or polypropylene are available from stock on short delivery.

How do they work?

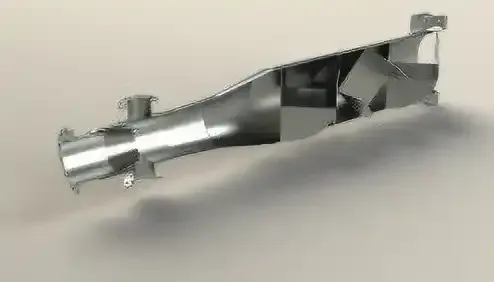

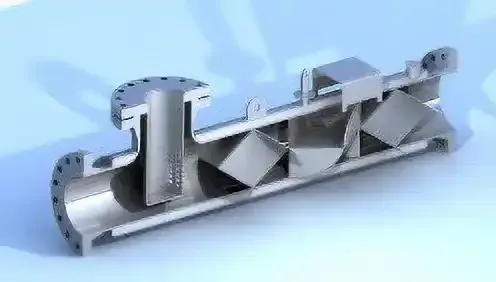

Advanced connection technology between the process tube and mixer elements on Euromixers-Primix Heat Exchangers results in a heat exchange transfer rate equal to that of the base material of the process tube and mixer elements. Each spiral shaped mixer element acts as additional heat transfer area, resulting in a 20 – 100% improvement in heat transfer compared to conventional heat exchangers.

Reliability & Performance

Compared to other types of heat exchanger Euromixers-Primix static mixer heat exchangers have a considerable advantage by reducing temperature differential over the cross sectional area of the process tubes, resulting in uniform product quality and a broad acceptance for heat exchange applications with higher viscosity process media.

Heat Exchanger

The high operational reliability of static mixers and heat exchangers has proved invaluable in a number of crucial applications in the chemical, petrochemical, pharmaceutical and food industries.

Heat Exchangers

Need a custom design?

If you're not sure what type of mixer you need, or would like more information, please get in touch and we can organise a video or on-site inspection of your premises to work out your ideal mixing solution.

Contact Us

We will get back to you as soon as possible

Please try again later